ในโรงงานในปัจจุบัน สิ่งสำคัญคือพนักงานต้องได้รับสภาพการทำงานที่ดีและปัจจัยภายนอกไม่ควรเข้ามาแทรกแซงกระบวนการ คุณสมบัติหลักสำหรับการทำงานที่มีประสิทธิภาพรวมถึงคุณภาพของอากาศ ด้วยเหตุนี้ เทคโนโลยีที่ใช้ในพัดลม HVLS จึงมีประสิทธิภาพมากขึ้นเรื่อยๆ วัตถุประสงค์ของเรียงความนี้คือการตรวจสอบวิธีที่พัดลม HVLS สามารถปรับปรุงอากาศภายในอาคารได้อย่างมีประสิทธิภาพรวมถึงข้อดีและการออกแบบของพวกมัน

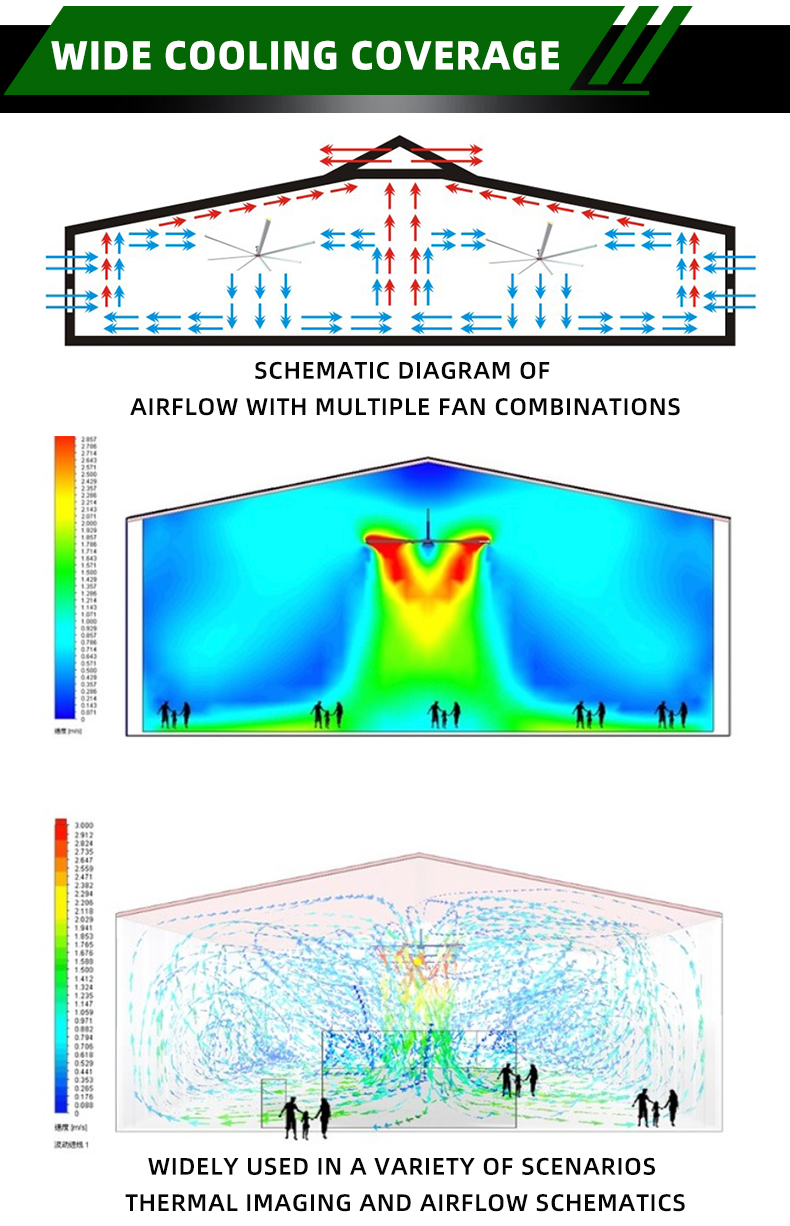

พัดลม HVLS ถูกออกแบบมาเพื่อให้มีประสิทธิภาพในการเคลื่อนย้ายอากาศในปริมาณมากที่ความเร็วต่ำเพื่อสร้างลมในพื้นที่ที่ต้องการการระบายความร้อนในสภาพอากาศที่อ่อนโยน พัดลม HVLS ถูกออกแบบมาเพื่อกระจายอากาศทั่วทั้งห้องแทนที่จะเป็นเพียงจุดเดียว เช่นเดียวกับพัดลมแบบเดี่ยว นอกจากจะเพิ่มความสะดวกสบายแล้ว การกระจายอากาศอย่างสม่ำเสมอในห้องยังช่วยลดโอกาสที่อากาศจะนิ่ง ซึ่งจะช่วยให้เกิดการเจริญเติบโตของมลพิษและสารก่อภูมิแพ้ ด้วยวิธีนี้ พัดลม HVLS จัดการการไหลของอากาศได้อย่างมีประสิทธิภาพเพื่อป้องกันการสะสมของมลพิษในอากาศและปรับปรุงคุณภาพอากาศ

นอกจากนี้ พัดลม HVLS มีความสำคัญมากเมื่อพูดถึงการใช้พลังงาน ระบบ HVAC ที่พบมากที่สุดมักจะทำงานหนักเกินไปเพราะพวกเขาพยายามที่จะส่งมอบอุณหภูมิที่ร้องขออยู่ตลอดเวลา ทำให้ค่าใช้จ่ายด้านพลังงานสูงขึ้น สิ่งที่สำคัญที่สุดคือ แตกต่างจากระบบเหล่านี้ พัดลม HVLS สร้างเอฟเฟกต์ลมเย็นที่ช่วยลดโอกาสในการทำงานหนักเกินไปของระบบเหล่านี้ตั้งแต่แรก พวกเขาช่วยให้สถานที่ต่างๆ สามารถปรับเทอร์โมสแตทให้สูงขึ้นในช่วงฤดูร้อน ซึ่งนำไปสู่ค่าใช้จ่ายด้านพลังงานที่ต่ำลงมาก ดังนั้น การใช้พัดลม HVLS ในการใช้งานอุตสาหกรรมจึงช่วยเสริมสร้างเป้าหมายการพัฒนาที่ยั่งยืนและเป้าหมายความรับผิดชอบขององค์กรอย่างแน่นอน

พัดลม HVLS ยังมีประโยชน์มากในการเพิ่มขวัญกำลังใจของพนักงานเนื่องจากการลดต้นทุนพลังงานในขณะที่เพิ่มผลผลิตของพนักงานไปพร้อมกัน มีหลักฐานมากมายที่ได้รับการสนับสนุนจากการศึกษาแสดงให้เห็นว่าสภาพแวดล้อมการทำงานที่ดีมีผลกระทบเชิงบวกต่อสมาธิและระดับผลผลิตของคนงาน พวกเขาใช้พัดลม HVLS ซึ่งให้คุณภาพอากาศที่ดีและการควบคุมอุณหภูมิที่ช่วยให้พนักงานทำงานได้ดี นอกจากนี้คุณภาพอากาศที่ดียังสามารถลดจำนวนการเกิดโรคที่เกี่ยวข้องกับการหายใจและโรคอื่น ๆ ซึ่งนำไปสู่การลาป่วยที่น้อยลงและแรงงานที่มีประสิทธิภาพและมีสุขภาพดีมากขึ้น

อุตสาหกรรมยังคงสร้างสรรค์นวัตกรรมในด้านพัดลม HVLS รวมถึงคุณสมบัติการออกแบบและระบบควบคุม เมื่อเทคโนโลยีมีความพร้อมมากขึ้น พัดลม HVLS ที่มีประสิทธิภาพจึงถูกผลิตขึ้นซึ่งใช้ระบบควบคุมการไหลของอากาศ ปรับระดับอากาศตามสภาพแวดล้อมภายนอก ขอบคุณสิ่งนี้ การเคลื่อนไหวของอากาศจึงไม่เพียงแต่มีประโยชน์ แต่ยังได้รับการปรับให้เหมาะสมและมีประโยชน์สูงสุดในการใช้พัดลม HVLS ในการใช้งานในอุตสาหกรรม นอกจากนี้ ผู้ผลิตหลายรายกำลังมุ่งเป้าไปที่วัสดุสีเขียวและมอเตอร์ที่ประหยัดพลังงาน ซึ่งจะทำให้สามารถพิจารณาพัดลม HVLS เป็นทางเลือกในการประหยัดพลังงานได้

สรุปแล้วมีหลายอุตสาหกรรมที่ควรใช้พัดลม HVLS เพื่อปรับปรุงคุณภาพอากาศ ความสามารถในการเคลื่อนที่ของอากาศและประสิทธิภาพในการใช้พลังงานของพวกเขา ขณะเดียวกันก็เพิ่มผลผลิตของพนักงาน เป็นส่วนสำคัญสำหรับทุกสถานที่ ด้วยอุตสาหกรรมที่มากขึ้นที่นำมาตรการด้านสุขภาพและความปลอดภัยควบคู่ไปกับแนวทางการพัฒนาที่ยั่งยืน ระดับการเข้าถึงพัดลม HVLS ในธุรกิจอุตสาหกรรมจึงมีแนวโน้มที่จะเติบโต สร้างมาตรฐานใหม่ในการจัดการคุณภาพอากาศในสำนักงาน การนำเทคโนโลยีพัดลมเหล่านี้ไปใช้มีแนวโน้มที่จะช่วยให้ธุรกิจสามารถก้าวทันการเปลี่ยนแปลงในอุตสาหกรรม เช่น ระดับคุณภาพอากาศภายในอาคารที่เพิ่มขึ้นและประสิทธิภาพการใช้พลังงาน

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

KY

KY

ออนไลน์

ออนไลน์